-

Celsius

Celsius

-

Acusia

Acusia

-

Graph theory

Graph theory

-

Amino acid

Amino acid

-

Hubble's law

Hubble's law

-

Amplexus

Amplexus

-

Smoltification

Smoltification

-

Benign

Benign

-

Ligand

Ligand

-

Body Mass Index

Body Mass Index

-

Meridian

Meridian

-

Neurochip

Neurochip

-

Composite skeleton

Composite skeleton

-

Antarctic

Antarctic

-

Oil producing plant

Oil producing plant

-

Cryogenian

Cryogenian

-

UMTS

UMTS

-

CGB

CGB

-

Diurnal parallax

Diurnal parallax

-

Lungfish

Lungfish

-

PAP

PAP

-

Newton

Newton

-

Geophagia

Geophagia

-

Hydrogel

Hydrogel

-

Senescence

Senescence

-

Colitis

Colitis

-

Noise

Noise

-

Oven

Oven

-

Lithospheric

Lithospheric

-

BOD5

BOD5

Polymerisation

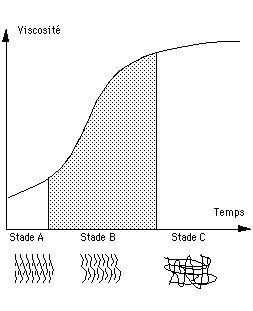

Polymerisation is the process transforming a monomer, or a mixture of monomers, into a polymer.

Polymerisation is a time and temperature dependent chemical reaction which, for thermosets, leads to the irreversible solidification of a matrix or resin.

Stages A, B and C define the various states of a thermosetting resin (or system).

At stage "A", the base resin and hardener have not been mixed (or have been mixed but have not yet reacted). They have low viscosity, a low mean molecular mass (the resin containing monomers) and total solubility. If stored correctly, they change little or not at all.

At stage"B", the system (resin + hardener) has started to polymerise (prepolymerisation). This is the gelling stage in the prepregs (the pre-impregnated fibres). This stage is not stable and can change (generally very slowly) to stage "C". To avoid this, the reaction is arrested by cooling.

At stage "B" the system:

• has good mouldability (high viscosity but the material is still fusible);

• lends itself easily to shaping and draping (in prepregs);

• is partially soluble (sometimes still totally soluble);

• has a relatively high mean molecular mass with little residual monomer.

At stage "C", the polymer is cross-linked. It is totally insoluble and infusible.

Polymerisation

Latest

Fill out my online form.